Let’s take a look at large-sized craft breweries (who, generally speaking, produce over 100k BBL annually) and the most common business challenges they face.

When breweries reach this level, it’s all about bringing things together. Managing multiple production facilities, defining more precise operations with process steps built into recipes, and integrating with control systems. This is accomplished by implementing advanced functionality in a brewery management software such as VicinityBrew.

Breweries at this level typically have already implemented some sort of brewery management software and have a need to formalize processes and dive into deeper, more complete data while managing various operations at times between multiple facilities. These companies have the infrastructure and bandwidth to support a traditional ERP system and are prepared to invest resources into fully implementing their brewery management software. As demand increases, so does the need for systematic procedures and uniformity throughout the brewery.

Growing Pain: Lack of Standard Brewing Processes Per Recipe

Solution: Centralize Your Brewing Process

As a brewery matures, older brewing methods become much more complex. What started out as a list of ingredients and simple instructions just won’t cut it as the brewery grows. Making consistent beers in larger volumes becomes an ongoing challenge. This requires standardization and communication of those processes and procedures.

One method of communicating standards is to define process steps in the recipe or formula. This may be related to how raw materials are introduced or specific equipment settings needed for a style of beer. The formula becomes more than just a list of ingredients and instructions but also a communication tool to assist the brewers, fermenters, and packers.

VicinityBrew Software allows a brewmaster to define the beer making process using Unit Procedures, Operations, and Phases. Many of you may recognize this as the S88 standard to communicate to control systems. VicinityBrew has embedded that three-level structure in the core formula architecture. This provides a format to better define the steps and processes to make beer.

One way to communicate specific technical information is by creating user-defined parameters. Breweries may want to communicate machine settings, transfer rates, resting times, and a whole host of other information. Materials, instructions, labor, QC tests, results, and parameters or target ranges can also be defined. This gives the needed structure to breweries increasing in production volume. A brewery in its emerging stages may not have the need to centralize brewing processes, but as they grow this becomes crucial. VicinityBrew addresses this need out of the box and is ready to provide the added detail structure when the time is right.

Growing Pain: Difficulty Scheduling with Multiple Locations

Solution: Utilize Software that Can Handle Different Brewery Locations

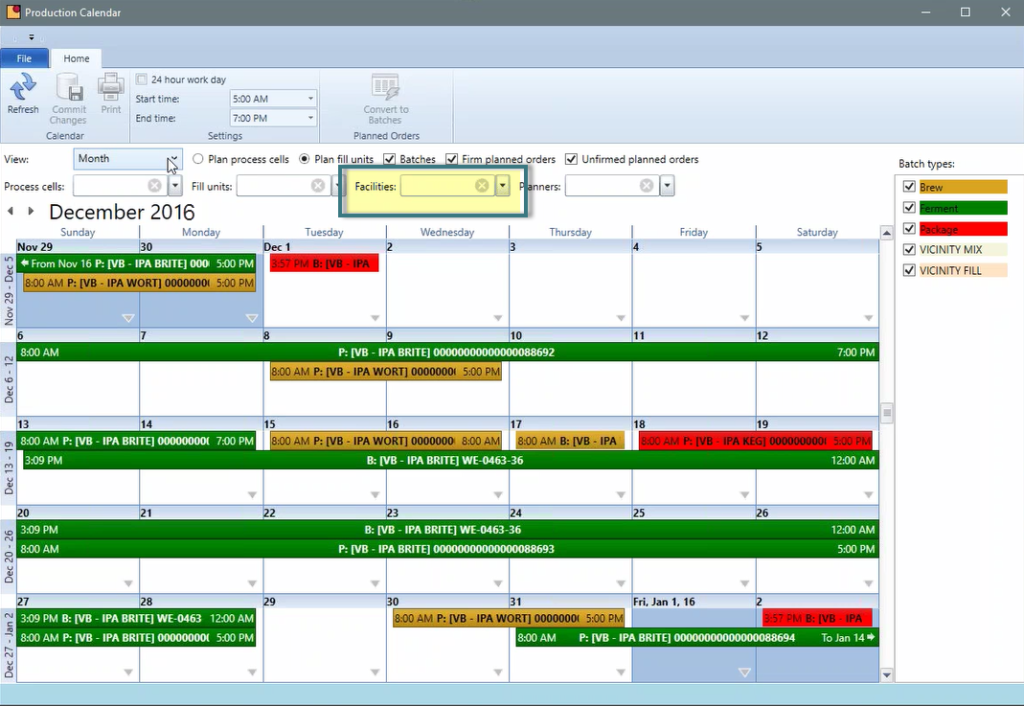

VicinityBrew also allows you to account for multiple brewery locations. This allows breweries to consistently produce the same finished good or SKU from multiple locations. For example, a production facility in California will have different equipment, different climate, and even different water from a facility in North Carolina.

With VicinityBrew software, breweries can define the beer making process specific to each facility. The result is a standard quality and consistency in every SKU. Therefore, a specific brand of beer made in that brewery’s California facility will be indistinguishable to that brand produced in their North Carolina facility.

Growing Pain: Software Isn’t Integrated to Brewery’s Control Systems

Solution: Software that Uses Industry Standards for Recipe Management

VicinityBrew’s recipe management module and hence, our production logs, were developed following the industry standard of S88.

What is S88 exactly? Well, S88 (shorthand for ANSI/ISA-88) is a database design philosophy for batch manufacturers in relation to equipment and procedures. The standard provides a structure for coordinating and integrating recipe-related information across the traditional ERP, MES, and control domains.

VicinityBrew adopted this S88 industry standard in the creation of recipe management, so when it is time for a brew log to talk to the control system that is running the brewhouse, such as Delta-V or Braumat, it will marry up. By connecting systems, data can easily be transferred and recorded, such as times, temperatures, and flow rates, directly to and from your brew log.

As your brewery expands, possibly to multiple locations, you will find the need to centralize controls:

- defining uniform procedures to support consistency on a larger scale and different brewers.

- connecting your ERP system to a control system to better share information and bypass manual data entry to focus on process review, analysis, and optimization.

- managing different physical locations to support various production environments resulting in consistent, quality beer.

If you would like to learn more about VicinityBrew software or want to schedule a demo, contact us today! If you’d like to learn more about the challenges and solutions for small or medium-sized breweries, check out our other linked blogs.