Integrated Quality Control Tests

Does your system currently track QC tests and tie them in with other operational data in your system?

At some point in the life cycle of a brewery, tracking and analyzing quality data of ingredients and operations will become important. VicinityBrew can connect the quality data with the formula and the logs. This allows a quality manager to assess what is going on with a recipe, ingredient, or process in an automated fashion.

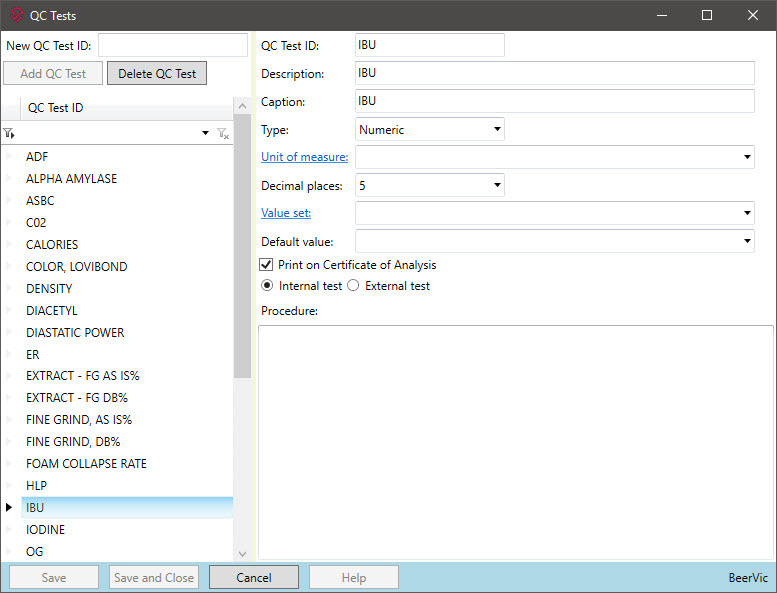

- Choose from an array of QC tests from VicinityBrew’s default library, such as pH, gravity, dissolved oxygen, CO2, micro-organism, daily tank checks, etc.

- Define an unlimited number of your QC tests including sensory data, notes, and observations

- Associate specific tests to raw material categories or add new tests on the fly as needed to individual items

- Correlate tests with designated brews

Inbound Raw Material Tests

Do you currently have a way to track quality data regarding purchased ingredients?

Over time, ingredients used in a formula can fluctuate from when the formula was created. This change can affect future brews if not addressed. Reviewing the supplier COA to ensure it is in an acceptable range can help to address issues before they arise. VicinityBrew provides a place to store the standards and enter the actuals if needed.

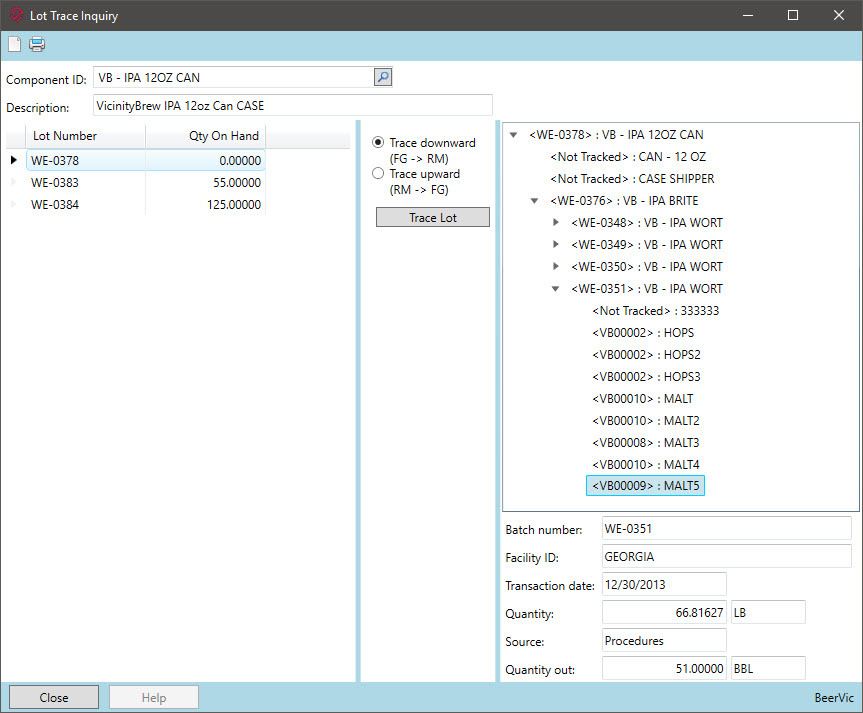

- Incorporate stored vendor Certificate of Analysis (CoA) to raw-material lots for future reference

- Associate the CoA with all subsequent records — wort, bright beer, and everything packaged from that brew

- View and print the CoA on demand

- Calculate and review brew variations with a clear baseline of raw material QC test results

- Set acceptable target values or parameters for each QC test

- Initiate an approval process of lots available, or released, for use in production

- Automate notifications for raw material results out of target test results

In-process quality control Tests

Do your current spreadsheets allow you to track the tests and observations during the brewing or fermentation process? What happens when you change a process? Where do you have to go to record those changes?

Defining quality tests and observations in the master recipe allows for centralized management of data. VicinityBrew supports quality data on the master recipe. This flows into the logs for each brew and fermentation.

- Quality control specifications within your recipes and inventory items

- Build quality test and instructions into your master recipe records

- Copy tests automatically from the master recipe record as batch tickets are created

- Set acceptable target values or parameters for each QC test

- Print required tests on your brew production logs

- Record or review tests assigned to batches during data entry of the actual test results, reducing the likelihood of missing new tests assigned by quality control or the Brewmaster

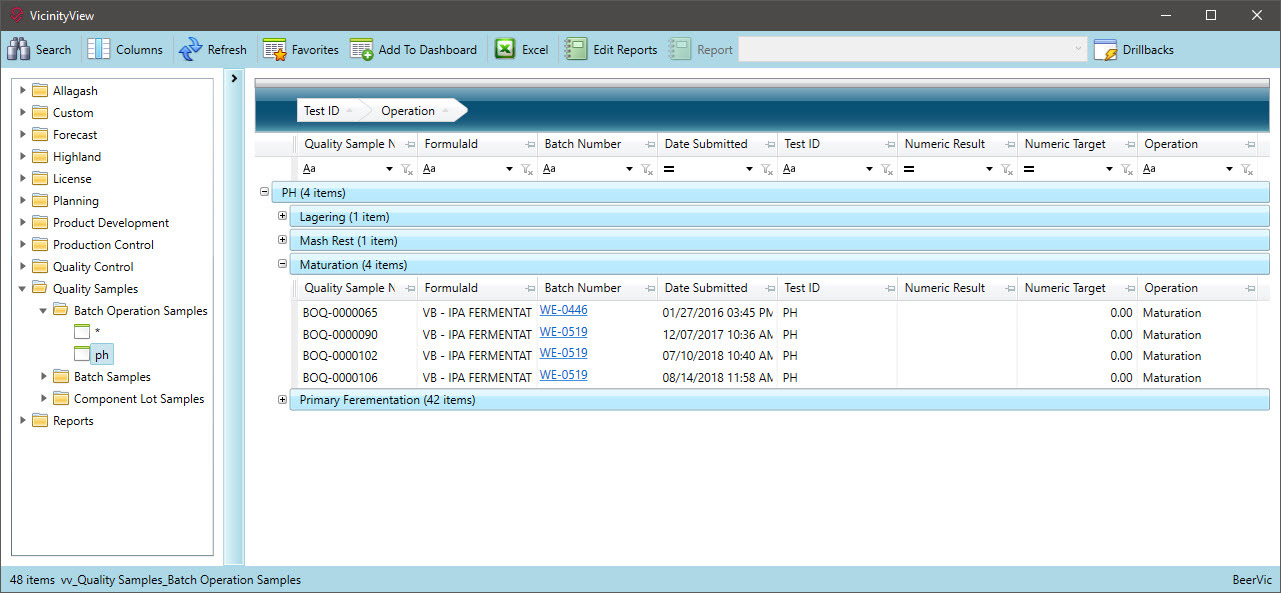

Evalutate formulas and analyze recipes by QC test results

Do you have the ability to look at specific QC results for the last 10 brews of a specific product? Can you easily track changes in your process over time?

Consistency is key for breweries. Most brews and fermentation recipes will shift over time. Having a system that allows you to track results along the way and review the trends for common products for logs is important to identifying and adjusting for these shifts. VicinityBrew allows users to define the process, record actual results in real time, and review the trends over time.

- Manage and track all test results by individual batch, recipe raw material item, or finished good

- Review test results over time and review the number of tests performed by recipe

- Identify, analyze, and adjust recipes requiring higher-than-standard adjustments effortlessly

- Target any of your products with a higher variability than others for review, resulting in a more streamlined brewing and fermentation process

Yeast Genealogy

Does your current system track which strains and generation of yeast was used in a fermentation?

VicinityBrew allows users to track the strain of yeast used in fermentation as well as the generation. Lot trace will reveal every fermentation log and packaged beer lot created from that strain. When you tie quality data to these logs, the yeast generation data becomes valuable and meaningful.

- Create yeast records and track as by-products or co-products to target and tag strains of yeast pitched through various batches

- Collect and define natural yeast attributes such as strain, attenuation, and flocculation rates

- Identify environmental factors of each brew such as times, temperatures, and associated elements, to understand potential impacts on yeast performance

- Track yeast genealogy and gather critical data to maintain your beer’s quality