Log Management

Is your beer brewing log and fermentation log created and managed from Excel?

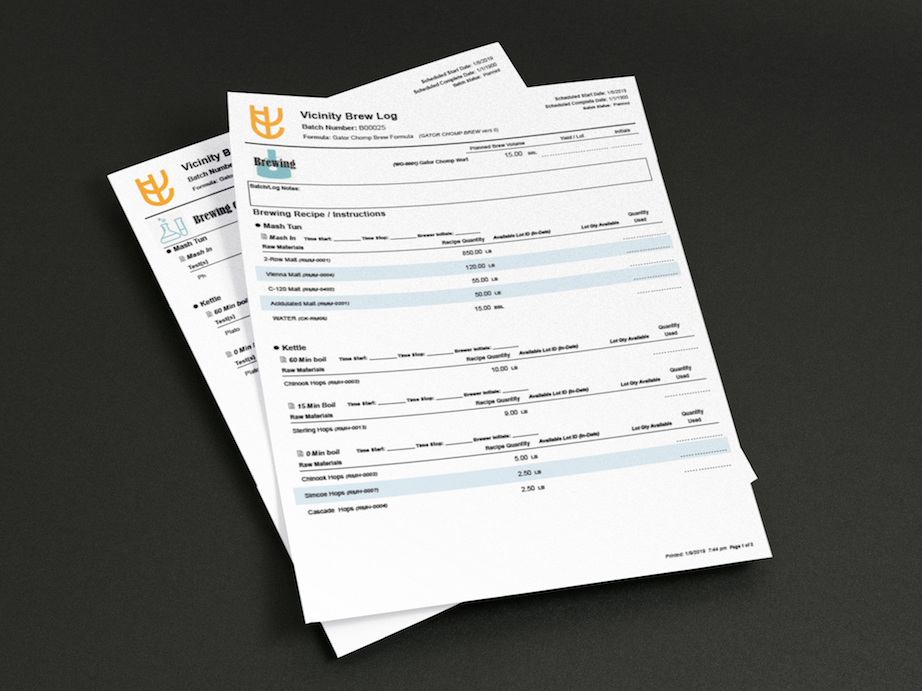

The brew, fermentation, and packaging logs are a key communication tool to breweries and brewery operations. Most breweries are printing them from Excel, writing all over them, summarizing the result in a financial application, and storing them in a big pile. VicinityBrew simplifies this process by pulling the formula from a common database, automatically updating inventory with ingredient usage and production results, and storing all results in a database that is easy to query results.

- Generate logs from the schedule

- Commit ingredient inventory in real-time

- Customize logs to meet your needs

- Include instructions, ingredients, and QC on the printed logs

- Consume ingredients in the middle of a process — dry hops

- Supports alternating proprietership

Daily tank checks

When fermentation tanks are checked daily, are results kept in a centralized database for easy reporting?

VicinityBrew assists the cellarmen in completing their tank checks in an efficient manner. All observations can be tied to the brand so the tolerances and notes can be brand specific. All brewery operations can be entered into a central location via the fermentation log or directly via a tablet.

- Record quality checks on the printed log or online via a tablet

- Provide detailed instructions of tank-check procedures

- Quality checks can be scheduled in advance

- Adjustments can be made on the fermentation log and inventory will be updated immediately

- All results are tied to the brand and tank for later analysis

- Unusual activity, like a power outage, can be noted in the data for subsequent review

Yeast Management

Can your current system track a strain of yeast from original through multiple generations without additional effort?

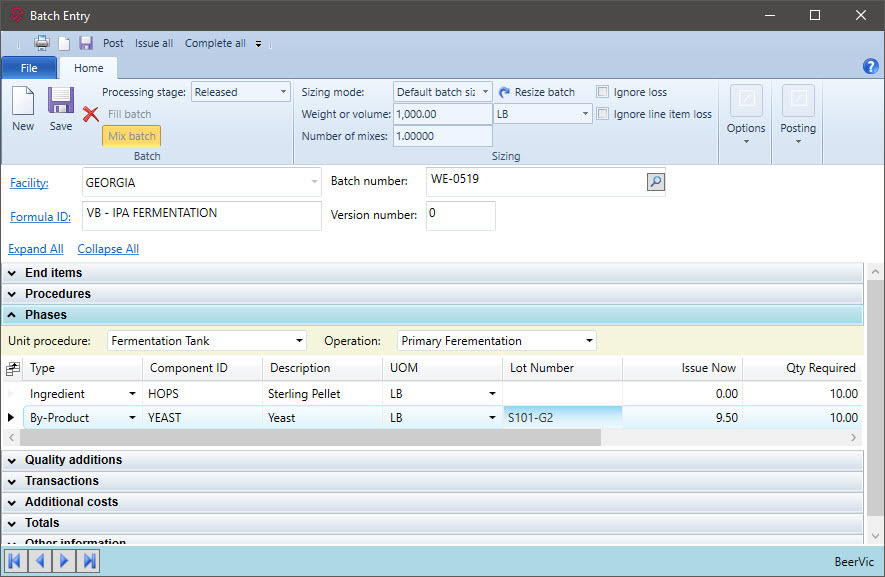

VicinityBrew provides a quick and reliable way to track yeast strains and the generations of usage. Yeast can also be propagated and traced to the originating strain/generation. This allows for ingredient usage and related quality data to be connected to the yeast genealogy.

- Assign a lot number to a yeast strain

- Each harvest of yeast from the fermentation tank increments the generation

- Supports cone-to-cone transfers if needed

- Connect quality and ingredient data for further analysis

- Propagation can be recorded via a log resetting the generation

- Full lot trace of all yeast generations within a strain

Contract Brewing

How does your existing system manage brewery operations of beer being made at another brewery or beer you make as a contract brewer for another brewery?

Some breweries leverage the capacity of another brewery and others brew on behalf of other breweries. There are unique challenges with both. VicinityBrew provides an easy-to-use, affordable, and efficient set of tools to meet these unique brewing needs.

- Supports using a contract brewer as well as being a contract brewer

- Supports alternating proprietorship

- Schedule and record contract brewery operations

- Segregate client-supplied inventory from production ingredients

- Generate separate TTB reports

- Does not require an additional license

Lot Recall

What steps would you go through to recall a product or track a lot through your existing process?

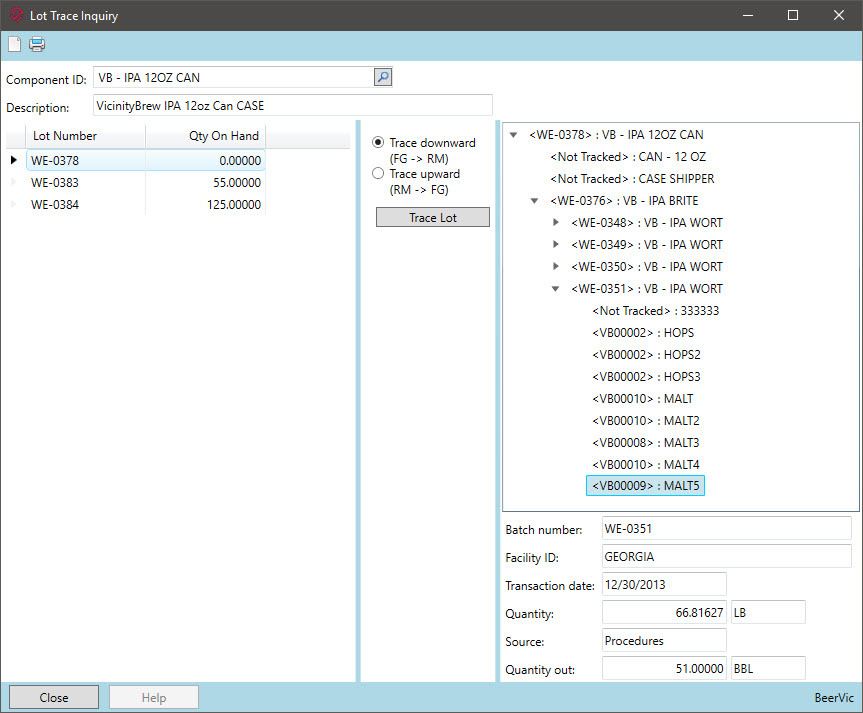

At some point, most breweries will face a lot recall as part of an audit process or in the event of a live recall. For most breweries, this involves a lot of manual effort to tracing through brewing, fermentation, and packaging. VicinityBrew automates this process. From hops through brite beer to packaged beer, VicinityBrew makes a lot trace a click away.

- Enabled lot tracking for some or all ingredients and produced items

- Lots are assigned at the time ingredients are received into inventory

- Lot tracked ingredients such as hops are consumed on a brew log, creating a lot of wort

- Wort is then consumed to make a lot of brite beer and then packaged

- Our simple user interface can trace from ingredients, through wort and brite beer to the packaged beer. This can also be done in reverse

- A lot trace report can be modified to address specific needs of the auditor

Real-Time material usage

In your existing system, can you record material usage (dry hopping) before the output (brite beer) is produced?

Breweries try to keep ingredient inventory levels low to preserve working capital and because they do not have excess storage space. So it is important to record material usage as soon as the inventory has been consumed. VicinityBrew supports the usage of ingredients to a log before the log is completed.

- Record ingredient usage immediately

- Utilize mobile entry or bar code data collection to speed up entry

- Anticipated ingredient usage is included on MRP until ingredients are consumed

- Ingredient costs are included on the log until the yield (brite beer) is recorded