For many breweries, brewing to capacity has been the number one constraint for individual growth. When your demand outpaces your supply, it often creates one of those uncomfortable situations that might be considered a “good problem to have.”

This scenario has been a common circumstance for many craft brewers. In response, many breweries have been investing in optimizing and expanding their production capabilities the best way they know how: with new tanks, systems and people.

What happens as your supply and demand begin to transpose?

Why should you adjust your growth strategy to correct for supply from outpacing your sales demand?

**Updated January 2024

If breweries continue brewing to capacity, regardless of decline or unmatched sales growth, coolers and storage facilities can fill up quickly.

Problems with Overstocking/Brewing to Capacity

- Decreased Shelf Life: By not having packaged beer in front of your consumer, you lose shelf life as products age Regardless of industry, location, or expertise in your craft, there’s no stopping time

- Cost of Physical Inventory: You spent the money to produce items, but are unable to recognize profits due to overstocking

- Limited Space: Overstocking can create dead space in your storage areas, consuming this space unnecessarily can disrupt the flow of materials and finished goods through your facility

- Spent Labor: Excess time dedicated to organizing and taking physical inventory counts

Breaking the Habit of Brewing to Capacity

Efforts to balance inventory, production and sales demand require increased visibility into your production flow and a tighter forecast of future sales. Taking the time to evaluate and measure your supply chain against sales demand will enable your brewery to:

• Run Lean: Save time and money from shifts and resources by only brewing what you need to fulfill sales orders

• Identify Brewing Opportunities: Does your brewery have extra capacity for contract brewing?

• Optimize Finished Good Production: Quickly adjust your packaging materials to follow the next sales trends for your product mix, such as switching between six-packs and various bundles

In talking to our brew clients, many explained the sense of crisis that an organization experiences in making risky decisions. The risky or “crisis-mode” decisions involve both danger and opportunity. Some breweries intentionally hold back growth and they might feel a strain, but some are now for being in crisis, asking questions to improve pricing, inventory and recipes. With the few years of the pandemic crisis (and coming out of it), all breweries (and businesses in general) have had to restructure, flex and make changes to stay afloat. At the beginning of 2020, breweries had an excess of product just sitting due to the shutdown and had to risk dumping their product and wasting time and money or figuring out a way to sell what they had. Unfortunately, much went to waste in those beginning months of uncertainty as the supply chain was disrupted, business shuttered and staff was laid off.

Most distributor or customer orders do not come in with enough lead time to drive your brewing schedule. Using a brewery management system you can gain real-time visibility into what products you have on hand, in production, and planned for the future.

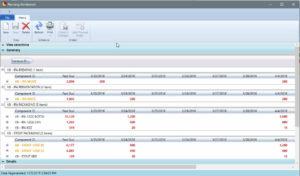

Evaluate inventory levels with associated production runs and schedule or firm-proposed production runs generated via MRP

By measuring directly against your sales orders or forecasted demand, you can narrow the margin for error and avoid an overstock situation. Utilizing these insights, brewers can break the habit of brewing to capacity and optimize their brewing schedule and product mix. VicinityBrew offers direct integrations with advanced forecasting software such as SkuBrain to stay ahead of packaging orders well before sales are input.

VicinityBrew can deliver a balanced system to streamline operations for your brewery across departments. Contact us today if you would like to learn more about our brewery management software.