Award-winning brewer enjoys “tailor-made processes” and software flexibility

“I told a neighbor brewer about the flexibility of VicinityBrew’s batching system. It’s not a one-size-fits-all system – Vicinity gives us the framework to build tailor-made processes throughout our product development and defines the processes in a way that fits what Allagash does.”

We spoke with Travis Emery, Senior IT Systems Manager, with Allagash Brewing Company about his experience with VicinityBrew software. He gave us a different perspective of the software, as he works exclusively with web services and data versus the typical user who interfaces with the front end.

The Situation

Allagash Brewing Company is an award-winning, independent craft brewery based in Portland, ME. Founded in 1995, Allagash is proudly a Certified B corporation, and it brews Belgian-style wheat beer, as well as wild, sour, barrel-aged and spontaneously fermented beers. Its core beers are distributed in 18 states and DC, and team members are based in Maine, with a sales force spread across the U.S. Allagash has been a customer of VicinityBrew since 2013 and uses Microsoft Dynamics GP.

Blast from the past: Watch this video interview with Allagash from a previous FOCUS customer event

The Solution

The flexibility of the VicinityBrew system and the ability to tailor processes to match lots of different mixing models and different processes/recipes for all its many beers – with different fermentation process – have been most beneficial to Allagash Brewing. VicinityBrew’s software solution allows people in the quality control, finance, supply chain, and production teams to work in a common source of batch information. Allagash can:

- Allow non-GP users (QC and Production users) to post Vicinity transactions

- Improve many accounting processes

- Using a handheld bar code data collection tool, brewers can post real-time transactions (ex. grain silo receiving) via Panatrack and GP

Before Allagash deployed web services, brewers used paper to manually record raw material and brew batch data, which was then transposed into Vicinity. Vicinity’s web services allow the Allagash team to pull data directly from its production SCADA (Supervisory Control and Data Acquisition), eliminating transposing work and potential error. Allagash now plans to use web services for all other downstream processes.

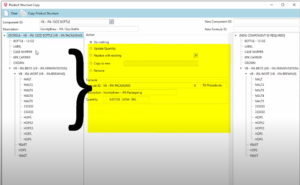

Product Structure Copy Tool

Another great feature is the Product Structure Copy tool, which allows Allagash flexibility in supporting some of its wild production maps. Being able to copy product structure and adjust to build a new product out of an existing product has been extremely helpful and accommodating with so many different brew batches. This is a useful tool for brewers.

“What I find most valuable about VicinityBrew’s offerings is costing and the capability to model out and do financial planning based on different models…that, plus lot tracking and the ability to identify and isolate batches that include components from different lots of materials. We use Dynamics GP as our general ledger and inventory management system. Vicinity Brew’s integration into GP is a big strength. The two together allow us to project inventory costs and manage costs at a batch level.”

The Success

There are so many factors that keep Allagash Brewing Company a loyal VicinityBrew customer. One of the most important is the developers’ willingness to engage with Allagash to advance the utility of the software to make the system more flexible

“The user group meetings have been really helpful. Vicinity engages us in product feature development discussions, and we’ve seen the benefits of their team’s development work with respect to individual feature requests. Specific functionality exists that came directly from our requests.”

Allagash Brewing Co., Portland, Maine

Other articles you might like:

5 ways to justify your brewery management purchase

Looking to invest in brewery management software